All About Rotational Molding and Its Process

Rotational molding is a approach that has been available for more than half a century. It enables suppliers to make plastic material parts with outstanding detail, using fewer uncooked resources than traditional processes. In this post, we are going to experience rotational molding from beginning to end and discuss the way it works.

Molds are produced by making an shot-shaped version or sculpture from clay-based or wax (or other delicate modeling medium). The done product is then provided a metal coating to ensure that when warmed up up, it can not burn during creation. Plastics are injected into these molds at high-tension charges where they awesome and harden quickly since they enter the sprue door on his or her way towards being molded items that are then ejected out of the mold.

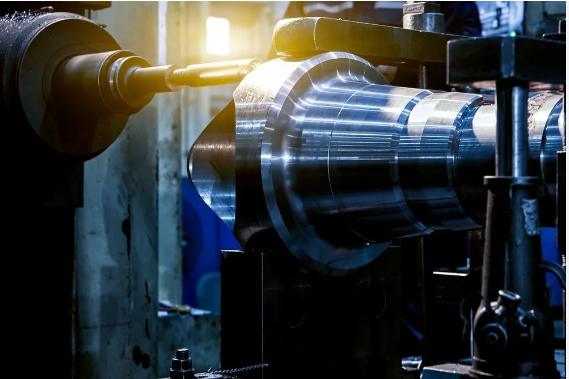

When plastic materials enter in a rotational molding device, they may be heated around about 270 diplomas Fahrenheit and injected right into a metallic-lined cylinder with frosty h2o coming from all instructions at high rates (around 100 gallons per minute).

The plastic goes in by way of a entrance called the “sprue,” which happens to be connected by hoses with an extruder mind that injects or integrates thermoplastic pellets for them to be rapidly cooled down and shaped. The revolutions within these cylinders build a vacuum result as molten plastic cools down off more than by itself as it does not have any atmosphere bubbles to result in chilling level of resistance. This enables for much quicker generation days of concluded items.

Rotational molded pieces can be produced with numerous ultimate looks. Rotational Molding is just how plastics can be produced to look like aluminum, window, or perhaps silicone. The fine detail that may be duplicated on each fungus is near limitless because of rotational molding’s power to develop incredibly sophisticated components all at once.

The rotational molding approach is very versatile and can be used as a variety of items, such as home furniture or huge components like vehicle bumpers. It’s also productive–taking about 90 minutes to create 120 pieces per hour.